The CES Series is designed to heat water for emergency eyewash stations and emergency drench showers to meet OSHA requirements. CES 12 kW through CES 36 kW units should be used solely for eyewash station applications. Depending on size, they will heat up to 7 gallons per minute by 35 °F (20 °C) and limit the output temperature to OSHA requirements. CES 48 kW through CES 144 kW units will meet OSHA requirements for many installations including emergency showers.

You must test your incoming water temperature on a cold day to verify the size unit you need to comply with requirements. Only the largest units will be sufficient for temperate climates. Customers should target 85 °F for best results and must attain 60 °F to meet regulations, which also require at least 20 GPM per minute per shower for 15 minutes to comply, plus the drench station at 3 GPM, plus the eyewash station requirements.

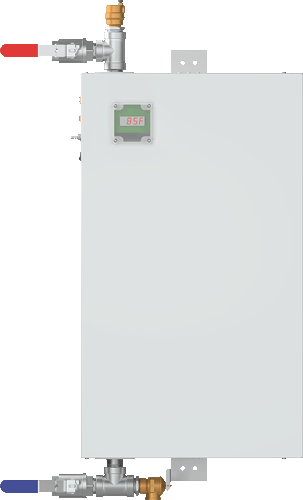

Features

- Electronic controls with minimal working parts

- Models CES 12 – 36 recommended in eyewash applications

- Models CES 48 – 144 recommended in safety shower applications

- Special air relief system affords increased reliability

- Dynamic load balancing ensures even element wear to improve longevity

- Factory set at 85 °F with maximum of 90 °F output

- Accurate to +/- 1 degree F

- Output temperature adjustable in one degree increments

- LED shows output temperature setting and flashes actual temperature if the customer is asking for more heat than is available

- Minimal pressure drop

- Individually fused elements

- Easily serviced on site

Options

- NEMA 4 and 4X enclosures

- External kill switch (requires NEMA 4 or 4X enclosure)

- 1″ and 1 1/4″ In/Out piping and valves available, depending on model

- Mixing valve available for varying output temperatures in 3/4″ – 1 1/4″ sizes